High reputation Food Grade Automatic Liquid Nitrogen Dosing Machine for Drink Filling

Our enterprise insists all along the standard policy of “product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation to start with, purchaser first” for High reputation Food Grade Automatic Liquid Nitrogen Dosing Machine for Drink Filling, For additional information and facts, please speak to us as quickly as possible!

Our enterprise insists all along the standard policy of “product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation to start with, purchaser first” for China Liquid Nitrogen Dosing Machine and Liquid Nitrogen Doser Machine, In the future, we promise to keep provide the high quality and more cost-effective goods, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

Parameter

Product Description

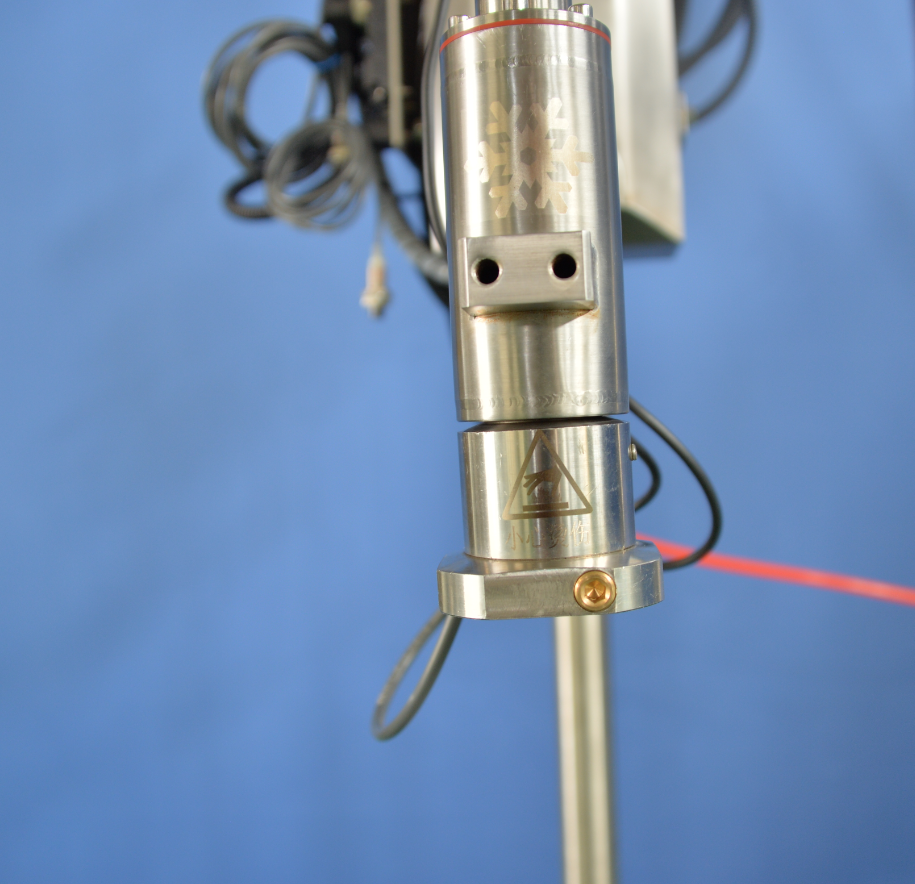

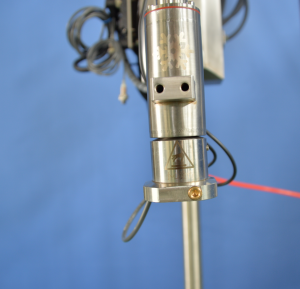

WYD-300 Liquid Nitrogen injection Machine for Pet bottle or aluminum can is the latest dosing machine in China .

It has the advantage of

Accurate dosing volume,

No-container-no-liquid dosing

Small size

Easy installation and maintenance

Suitable for any filling production line

Siemens PLC control system with touch screen,

Vacuum heat-insulated pipes ensuring minimum consumption of liquid nitrogen

No frosting operation condition

The liquid nitrogen dispenser is designed to create a pressure and inert environment in packaging containing “calm” liquids (such as oil, water, juice, wine, beer, low alcohol beverages, etc.) and food (ketchup, nuts, potato chips, breadcrumbs, etc.). This machine is suitable for any packaging container, including aluminum cans, glass, PET , and other types of plastic.

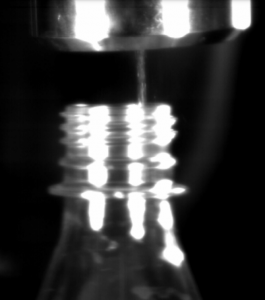

The ability to automatically create over-pressure and inert environments is a revolution in the packaging industry to some extent. After a drop of liquid nitrogen is injected into a bottle or container, the evaporation is strong (boiling point – 196 ° C)

When it becomes a gas, its volume increases by 700 times. This physical phenomenon can do two basic things:

First, before packaging, the remaining air and oxygen are squeezed out of the bottle and replaced with inert gas nitrogen, thereby extending the shelf life of the product;

Secondly, after sealing, the evaporated liquid nitrogen will generate additional pressure, greatly improving the rigidity and strength of aluminum, RET, and other plastic containers. This is necessary for reasonable storage and transportation, and to prevent the “vacuum rupture” effect of hot products when cooled in closed containers.

Using a liquid nitrogen dispenser, it is possible to successfully package cold liquids, hot ketchup, cooking oil, dessert syrup, wine or coffee concentrate into PET containers.

Liquid Nitrogen Injection Machine Working Process

When liquid nitrogen vaporized, the volume expansion 700 times, extrude the air out and vacuum the can,increase the aluminum can/pet can internal pressure to strengthen the package, Meanwhile, prolong canned food or beverage shelf life, keep good looking for better transportation and store.

Key Advantage when using liquid nitrogen injection machine

- Strengthen lightweight PET package – reduce the weight of PET for saving cost and environmental friendly requirement.

- Container rigidity – maintain shape even with lighter weight containers

- Oxygen reduction – Create an inert environment in container to keep product fresh

- Extend shelf life – minimize oxygen content

- Ease of labeling – consistent container rigidity creates an efficient labeling process

- Maximize warehouse storage space – increasing product stack ability utilizes less square footage

- Stabilize organic products – extend shelf life without preservatives

Liquid Nitrogen Dosing Machine Operation Conditions

1. Supple of Liquid Nitrogen: Regulate to 15 (0.1MPa) and connect to liquid nitrogen pipe.

2. Compressed Air or Nitrogen: Supply to the working of dosing valve.

The pipe diameter must be 1/4 inch and pressure range is from 50 psig to 100 psig (3.4 to 6.9 bar). Set the pressure to 50 psig (0.35MPa).

Please do not set the pressure too high, high pressure means high impact, it will shorten the lifetime of dosing valve element and internal vacuum pipe.

|

Technical Parameter: |

|

|

Capacity |

0-300/ 0-600/0-2000 cans per min |

|

Suitable Package Size |

Any size |

|

Power |

200W |

|

Voltage |

380V 50HZ 3 phase+N+G |

|

Weight |

85KG |

|

Dimension |

1230mm×770mm×500mm |

Product Charateristics

1. No container no dose and interval dose method in low speed to reduce liquid nitrogen consumption; dosing valve is always open in high speed. Automatic detects high speed or low speed.

2. Vacuum & heat insulation protection

3. Special nozzle care system effectively avoid nozzle frost and ice blockage phenomenon.

4. Liquid-gas separator ensures liquid nitrogen in an ultra cold state, improves liquid phase purity to make the dose more precision and steady.

5. Liquid nitrogen buffer function, effectively control liquid nitrogen bounce splash. Liquid nitrogen dosing amount is steady and ensures can pressure equality.

6. Filter(optional) 10 u m to remove particulate pollution

7. Precise dosing liquid nitrogen speed could reach to 300cpm, continuous dosing speed could reach to 800cpm

8. Capacity adjust ability and effectively vacuum liquid nitrogen insulation pipe ensures minimum liquid nitrogen consumption

9. Advanced dosing valve ensures transport pure and liquid nitrogen.

10. Lowest outlet pressure of dosing valve ensures minimum liquid nitrogen splash.

11. No frost operating condition.

12. Precise adjust ability of dosing amount and dosing time

13. Continuous self-monitoring through alarm indicator

14. PLC control/Touch screen/user- interface language selectivity

15. Could connect liquid nitrogen vacuum and heat insulation pipe, also could provide a complete liquid supply system from liquid nitrogen storage tank to fling production line.

16. Small size and easy to install

17. Diversity machine types ensure to suit different capacity production lines.

18. Apply to all different sizes pet bottles and thin-wall easy open cans production lines.

Please contact us for more details for liquid nitrogen dosing machine

Zhoushan Willman Machinery Technology Co.,Ltd

Address: NO.69 Xinychi Road, Donggang Sub-district, Putuo District, Zhoushan,Zhejiang Province, China.

/

https://wellmantec.en.alibaba.com/

Tel.: 0580-3711813 Fax. :0580-3711813

Email : joanne@willmantec.com

Mobile/Wechat/Whatsapp : +8618042297890Our enterprise insists all along the standard policy of “product good quality is base of organization survival; client gratification could be the staring point and ending of an enterprise; persistent improvement is eternal pursuit of staff” and the consistent purpose of “reputation to start with, purchaser first” for High reputation Food Grade Automatic Liquid Nitrogen Dosing Machine for Drink Filling, For additional information and facts, please speak to us as quickly as possible!

High reputation China Liquid Nitrogen Dosing Machine and Liquid Nitrogen Doser Machine, In the future, we promise to keep provide the high quality and more cost-effective goods, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.